WIth our fixed geometry high shear processors, our customers can significantly reduce particle size and achieve uniform particle size distributions. The ability to create innovative products with uniform, unprecedented nanoparticles allows our customers to stay ahead of their competition, and develop new and improved products.

Small VolumeThe ShearJet® HL60 V2

Now Available in 110 VAC

The Dyhydromatics ShearJet® HL60 V2 processor is our R&D workhorse. It is an electric hydraulic driven processor designed for volumes ranging from 3 mL to 500+ mL. Pressures range from 5,000 to 30,000 psi. Each stroke is 1 mL which generates a flow rate up to 68 mL/min.

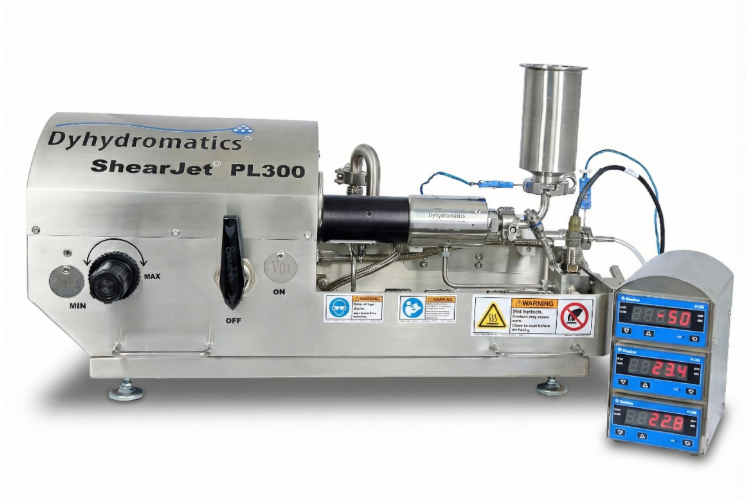

Medium VolumeThe ShearJet® PL300

Tight Distributions of Formulations

The ShearJet® PL300 processor is a small pneumatic driven processor which is available in non-pharma and pharma versions. Both processors generate pressure up to 23,000 psi with a stroke volume of 6 mL. The non-pharma model handles a sample size of 45 mL and up.

Medium VolumeThe ShearJet® HP350 V2

NEW Model

The ShearJet® HP350 V2 series electric-hydraulic processor operates with a single multiplier pump which processes 80 mL to 50 L and higher sample sizes and high flow rates in distinct passes or continuous runs. Its reliable and robust design makes the HP350 V2 model a, viable option for R&D and pre-pilot scale applications. Its integrated HMI with data acquisition capabilities is very user friendly and easy to read. Its small compact design and casters, makes transport between lab suites seamless.

Pilot ScaleHP1200 V2 Series

Less Maintenance and Higher Reliability

The ShearJet® HP1200 V2 Series electric-hydraulic processor runs sample sizes of 1 L (options dependent) to 200 L and up in distinct passes or continuous runs. Because the HP1200 V2 series is equipped with two multiplier pumps, it achieves near-continous flow, subjecting formulations to identical processing conditions from start to finish. The HP1200 V2 is capable of operating from seconds for smaller samples or continuous for very large batches.

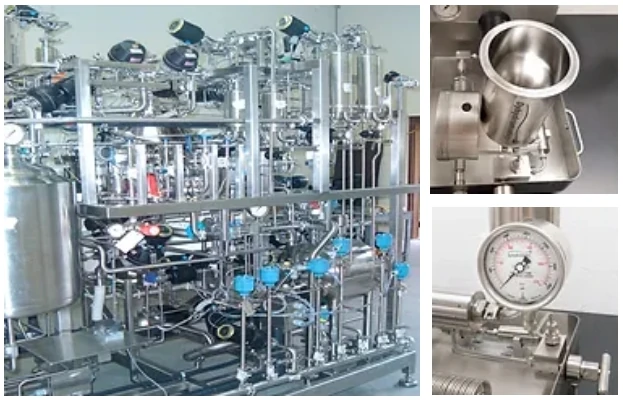

Pilot ScaleFeed and Skid Systems

Are You Ready for a Completely Integrated Solution?

Let us design a complete turnkey system to improve your upstream and downstream process that will improve your results, reduce your maintenance costs and extend your machine’s usable life — With our partners, let us design a complete turnkey system to improve your upstream and downstream process that will improve your results, reduce your maintenance costs and extend your machine’s usable life.